Wednesday, November 19, 2008

The virtuous cycle of organics

- Organic farming techniques result in improved soil quality and fewer chemicals entering into the environment.

- Improved soil quality results in better water retention, reduced run–off and a higher nutrient content.

- Reduced run–off along with reduced chemical usage results in cleaner water systems.

- Reduced pesticide usage results in an increase in biodiversity and strengthened eco–systems.

- The reduced chemical input means less energy is being spent to product petro–chemical based fertilizers.

- Reduced energy and fossil fuel consumption means reduced emissions and therefore cleaner air.

- We get healthier food, cleaner water and cleaner air resulting in healthier, happier people.

- When people choose organic products over the alternatives it encourages farmers to choose organic methods, therefore strengthening the positive cycle.

- GM crops encourage the use of herbicides (like Monsanto's Round–up ready crops).

- Farmers cannot propogate their crops (which hands over food security to large corporations) or develop seed varieties suited to their soil and environment.

- Conventional methods require the addition of chemical fertilisers to maintain soil quaility.

- Exclusive use of chemical fertilisers results in a narrow spectrum of nutrients in the soil.

- Fertilizers, herbicides and pesticides run–off and pollute the water system.

- Pesticides result in the death of beneficial birds and bugs.

- More energy and fossil fuels are spent on the production of chemical fertilisers, herbicides and pesticides, resulting in more emmissions and dirtier air.

- Potential health concerns exist.

- Lower quality food as well as dirtier air and water – more unhealthy and unhappy people.

Cost is a factor of supply and demand, but is also influenced by organic certification costs which are high and ongoing. Small organic farmers are often unable to afford full organic certification, but their non–certified organic goods may be available at better prices through farmers markets, co–ops and CSAs. If costs is an issue, but you want to reduce your pesticide intake, then you can focus on choosing organic varieties of the top offending foods on this list.

If you are in Cape Town or the surrounding areas you can get reasonably priced organic produce from fully certified, as well as non–certified, organic farmers via The Ethical Co–Op.

Photo courtesy of Jennifer Dickert, licensed under a creative commons license.

Wednesday, November 12, 2008

Take action. Be a leader

What you do matters. What you do each day matters. The decisions that you make are important.

What you do matters. What you do each day matters. The decisions that you make are important.Sometimes we forget that our role, our decisions and our actions play an important part in the world around us. It is especially easy to forget when we are faced with overwhelming circumstances or events. Many people who care about the environment feel overwhelmed by the scale of the challenges we face. In that same way many businesses and households are reeling in the face of a global financial crisis.

It is so easy to go into a state of stasis – doing nothing, or just reacting to our immediate challenges. The worst thing to do is nothing. Reacting may mean reducing your budget and cutting out excess spending. It may be reducing your environmental impact by buying less stuff. The problem is that reacting is defensive, like pulling your hand away from a hot stove. If you are always defending you are never going anywhere and standing still is a bad idea in a rapidly changing world.

Responding is better, initiating is best. When we respond we take positive actions, actions which improve our lives rather than deprive them. Environmentalists often go wrong by focussing on what we need to take away rather than on how we can improve and benefit our lives right now, but we know from dieting that deprivation is a temporary solution which leads to overindulgence. Respond by adding positive actions.

When we initiate we go beyond ourselves. We push beyond our own personal boundaries and lead people to new places. Creating new innovative products or processes in a slow market is initiating. Starting a recycling programme within your community (your street or neighbourhood) is initiating. Everyone has the opportunity to be a leader, whether you are a young engineer trying to push new ideas into a big company, or a housewife who wants to create a better life for your family. You may lead just a few people, or many – what matters is that you take action. We need you to lead.

Taking action is difficult and requires consistency and effort, so I would like to leave you with this story about Jerry Seinfeld.

Jerry says that to be a better comic you have to create better jokes, and to create better jokes you have to write everyday. He puts a big calendar on a prominent wall and every day that he fulfills his task of writing a new joke he gets to put a big red cross on the calendar. After a few days of doing this consitently you will have a chain. Jerry says, "Your only job is to not break the chain. Don't break the chain."

Innovate, be consistent, keep taking action, what you do matters. We need you to lead.

Kudos to Seth Godin and his book Tribes which inspired this post. You can get a free audio version of Tribes. Read the book or listen to the audio version – it is a valuable investment of your time and effort.

Tuesday, November 04, 2008

Open Source EDA

Most companies use expensive commercial tools (like those mentioned above) which offer many features and benefits, but these do have some disadvantages. The biggest hurdle for smaller companies is cost, which makes it difficult to get going – you cannot earn money to pay for the tools without using the tools, which is a vicious circle. Another big disadvantage of commercial tools is their closed nature – file structures are closed and it is difficult to add custom features to the tools. Further to this, if you need improvements or bug fixes you may have to wait a long time before these become available, especially if you are a small customer. In some cases companies are bought out, forcing you to change software and go through a whole new learning curve. To phrase it differently: small users have little say in the direction of the development of the tools.

The big advantages of commercial tools are the multitude of features (if you need them), and commercial support.

When I had to choose an EDA tool suite my (non–existent) budget was the biggest deciding factor and I decided to start using an open source set of EDA tools, gEDA. I have been using gEDA since the middle of 2007, and have completed a number of projects with it. At first I just did my schematic layout with gschem and outsourced the PCB layout which was done in PCAD. Recently I completed some PCBs for a project which where done with gEDA's PCB programme (this was my first entirely gEDA project).

I initially made my choice based on the free price of gEDA, but as I used it and learned more about how the suite works as a whole I discovered that there are far more compelling reasons to choose an open source EDA suite over a closed one.

The open nature of both the file structure and the source code is an incredibly powerful tool for productivity. Think about this simple example: the creation of PCB footprints (or land patterns). Creating footprints is often a long and arduous process which involves graphically drawing out exactly what it should look like and vetting the details. Each subtle variation on the footprint requires more time drawing and checking. The well documented open file format and excellent documentation on the creation of footprints for PCB allows scripts to be written to automate the creation of footprints resulting in a significant time saving. Similar scripts are also available for schematic symbol creation. These are really simple examples of what can be accomplished when the file structure and code is open and documented – far more exciting things can be done, just about anything you can think of!

gEDA is also blessed with a very active support and development community, which operates mainly through the gEDA mailing lists and the gEDA wiki (which provides excellent documentation). I have asked many questions and received quick and helpful responses. How long did your last support request with a commercial company take to be resolved?

Using an open source EDA suite provides more stability and control over the future of your tool chain. If a large commercial tool set is either bought out, or decides to change how it works significantly you have little choice but to embrace that change, whatever the cost or learning implications are. An open source EDA tool provides you with a never ending upgrade path for the future, as well as access to the direction the tool takes. This stability comes with a responsibility to be a part of a community, rather than just a consumer. By becoming a part of the community you create a mutualistic relationship where everyone benefits.

gEDA (or other open source EDA tools) may not be suitable for everyone, or for every project, but there are a large number of projects that can be supported by these flexible tools. Using gEDA does require a shift in the way you work, but so does any other change to your EDA tool chain. Putting in the effort to learn how to use gEDA is certainly worth it and offers the opportunity for large productivity leaps. These productivity leaps are important, as they ensure that engineers spend more time creating, designing and solving problems, rather than wasting hours on repetitive tasks. I am using it exclusively to provide solutions to my customers, and you should take a closer look at it too.

Here is a list of open projects created with gEDA. One of the most impressive open hardware projects that I have seen which uses gEDA is the Free Telephony Project, which not only shows the quality of these tools, but also the magnitude of what can be achieved with open hardware development.

Please note that files and projects created by you are entirely yours and can be used for commercial purposes without any ramifications. The projects noted above have chosen to share their work under open licenses.

There are no up–to–date Windows binaries available for gschem and I found that the PCB binaries were really slow. I run the entire suite on Cygwin. Here are the install instructions for gEDA on Cygwin. I also recommend compiling PCB on Cygwin for significantly improved performance.

I posted my thoughts on creating my first PCB with PCB to the gEDA mailing list – this may give you some ideas of initial hurdles and ideas that you will need to get through.

Monday, October 27, 2008

What I learned at the Natural & Organic Expo

- Polystyrene can be and is being recycled in Cape Town.

From the reading that I have done I thought that polystyrene was expensive and inefficient to recycle, mainly due to the problems associated with transporting such a light plastic, but polystyrene is actually collected, melted into ingots and recycled into picture frames, stationery, cornices, skirting boards, hangers and seedling trays. In Cape Town EPS Reclaim in Montague Gardens collects and smelts polystyrene. Find your nearest polystyrene drop off point.

- There is clearly a big demand for natural cleaning products.

I was amazed at how many different natural, organic and bio–degradable household cleaning products were on show. The demand and acceptance of these products is growing not just for environmental reasons, but also due to health concerns such as allergic reactions.

- Oxi-degradable plastics are creating headaches for recyclers.

I have written about oxi–degradable plastics before. It is important to realise that oxi–degradable plastic is very different from bio–degradable plastic. Companies like Green Home make bio–degradable plastic from plant sources (in their case bagasse, a byproduct of the sugar industry), while oxi–degradable plastics are normal plastic (like polyethylene) with the addition of a metal salt which causes them to break down over time. In South Africa oxi–degradable plastics have been used mainly for fruit and bread bags. The problem with these types of plastics is that they are indistinguishable from normal plastics and it is difficult to know how far the degradation process has progressed. Oxi–degradable bags pollute the recycling stream and result in a poor quality end product.

- Bio–degradable plastics require education and infrastructure.

Bio–degradable plastic products made from sustainable sources (such as bagasse, mentioned above) may provide a viable alternative to plastic in some cases. It is important that they are manufactured from sources other than food crops (plastic from corn is unsustainable). A problem that needs to be addressed (and is being addressed by manufacturers such as Green Home) is how to manage the waste from these products. Simply dumping bio–degradable plastic into a landfill is undesirable. Bio–degradable plastics will not degrade in a landfill, which means effective collection and composting needs to take place. Consumers can compost these packages at home, but without education it is unlikely that this will happen. Education, collection and composting infrastructure is an important aspect of bio–degradable plastic.

- Egg yolks contain colourant.

Pick 'n Pay is selling a new range of indigenous free range eggs, and one of the marketing points is "No yolk colourants." Yolk colourants? It turns out that chicken feed is often supplemented to increase its carotenoid content to obtain a more consistent colour yolk. The supplements used appear to be natural or "nature identical" such as lutein and canthaxanthin.

Monday, October 20, 2008

Light and heavy symbols

As an electronic engineer you have probably been through it. It all starts simply and clearly. You need to draw a schematic; so you make some symbols, attach some attributes to them and get going. Then you draw some footprints for the PCB layout and make sure the correct footprint names are attached to the components you have created. The boards go the PCB manufacturer and you use a simple spreadsheet to manage the bill of materials (BOM). Everything goes nice and smoothly – you are happy.

Then another project comes along – a bigger one with more engineers working on it. You carry on like you have before, explaining to people how to create new components and footprints and how to make sure the part numbers are correct. It all seems to be going well. The PCBs and components arrive, but something is not quite right. One of the components (an expensive one!) is the wrong part, and another component does not fit onto the PCB footprint correctly (even though there is another component with the same footprint that does fit correctly). What went wrong?

Eventually with more projects and more people managing the component library becomes a full time job for someone, and getting a new component approved is a lengthy process for engineers. Let's not even talk about managing the now massive stock and BOM spreadsheet which keeps you awake at night. The quick process you started with has become a slow moving, time consuming beast. We need to find a way to kill that beast so that engineers can spend more time creating solutions to problems, and less time on administration.

There are two ways to handles components. We can either have "heavy" symbols, or "light" symbols. First a few definitions so that we are all talking the same language.

| component | : | an actual physical part. |

| symbol | : | a diagram depicting a component which is placed in a schematic drawing. |

| footprint | : | the physical layout of a component on a PCB. |

A heavy symbol has all of its attributes, such as part name, value, voltage, tolerance, footprint, ordering number, etc. specified in the symbol library. A light symbol has no attributes specified in the library and all attributes are added at a schematic level.

There are some obvious flaws with each approach. A heavy symbol library will quickly grow in size – just think about having a symbol defined for each different opamp or resistor that is used. The graphical representation of an opamp is generic to a number of different parts, but now duplicates are created for each component. If a fault does creep into the library it can result in a number of different symbols needing to be fixed.

With a light symbol library all the attributes are added to the schematic. Maintaining the symbols is easy (because there are fewer), but ensuring that the correct attribute information is added can lead to errors (each time data is manually copied or entered there is the potential for an error).

There are also some obvious advantages. A heavy symbol immediately makes a lot of information available in the schematic which can be passed on to other tools, such as the footprint to the PCB layout package, or the part number to the BOM. A light symbol allows for information to be drawn from multiple sources, and the schematic can be updated without having to propagate the changes back into the library.

Here is a brief summary of the feature of each type of symbol.

Heavy symbols:

- Data duplication,

- Errors requires changes to numerous symbols,

- Require a librarian to maintain symbol library sanity,

- Single source of information.

- No data duplication,

- Errors can be fixed at schematic level, or only affect a single symbol,

- Allows multiple data sources for component information,

- Requires addition of attributes at schematic level.

The "light" and "heavy" nomenclature arose out of discussions on the gEDA mailing list. The gEDA wiki has a brief summary, and the two threads which I think are the most relevant are "Light vs. Heavy gschem symbols?" and "Heavy symbols and such."

Tuesday, October 14, 2008

Efficiency is the goal

Efficiency is the perfect use of material. Packaging is inefficient, as the "goal" is what is inside the package, while the packaging becomes waste. Packaging can be efficient if it is reused, as it never exits the system. Recycling requires extra energy, and is therefore less efficient than reusing, but more efficient than throwing away packaging. Using less to achieve the same is material efficiency. Smaller products, less packaging, lower material consumption. Have you ever considered how you could design exactly the same thing but smaller? Electronic engineers, think about small 0402 or 0201 size resistors over larger ones – in most cases they are functionally equivalent, but use less material and require less space on a PCB.

Efficiency is the perfect use of fuel. Internal combustion engines are around 20% efficient – that means 80% of the energy you put into your car is wasted. If cars were 100% efficient they would have zero emmissions and generate no heat. Did you know that cycling is the most energy efficient mode of transport?

Efficiency is the perfect use of water. Polluting potable water with waste such as sewerage and chemical cleaners requires energy and further chemicals to restore the water to a usable state. Efficient water usage means reducing consumption and leaving it in a usable state. Reducing waste and chemicals entering the water system means more efficient processing of water. Processing waste on site (composting toilets, greywater systems) reduces both waste and water consumption.

Solar energy is time efficient. Oil and natural gasses are the result of thousands of years of energy from the sun. Using the sun directly is an efficient time short cut.

Increasing crop yields makes more efficient use of space. Decreasing the use of fertilizers moves towards the perfect balance of an efficient ecosystem. Growing food near where it will be consumed is transport efficient. All our environmental goals centre around efficiency.

We need to learn from nature – waste nothing, strive towards perfect efficiency.

Tuesday, October 07, 2008

Cape Town green bloggers meet-up

Monday, October 06, 2008

Information duplication is the enemy of efficient systems

The electronic design process is made up of different parts such as schematic capture, PCB layout, component procurement and assembly. Each step requires information to be passed backwards and forwards. Certain information is only relevant to particular steps, for example you only need the exact part number for ordering, while a more basic part number or description could be used in the schematic (passives like resistors and capacitors are a good example of this).

Deciding what is important amongst all this information can be difficult, which often results in much of the information being duplicated in each step. The tools we use for electronic design automation (EDA) can inadvertently encourage us to create duplicate parts with detailed information contained within them. This seems fine until the parts library grows to an unmanageable size and discrepancies start to creep in, resulting in design and manufacturing errors.

Passing information between different systems, like the stock management and design systems can create an even larger mess. Typically these two systems are separated from each other and keeping them synchronised becomes a full time job. Any discrepancies between the two systems result in expensive time losses due to incorrect stock. The more information there is to keep track of, the greater the chance of errors and wasted time and money.

I am sure that most engineers have at some point in their career come across massive stock and bill of material spreadsheets which are overwhelming to manage, not just due to the amount of information, but also due to the incorrect tool (a spreadsheet) being used.

Yes, there are probably comprehensive ERP systems that can help with these problems, but those are not necessarily accessible to small engineering firms or individuals.

Information duplication is the enemy of efficient systems, we must eliminate it wherever possible.

That is the first rule of the process that I am developing for my own business. It will help me to develop faster and better, and once it is working it is going to allow every engineer access to the same opportunities.

Tuesday, September 30, 2008

Breaks

Taking breaks changes us. Long or short, they matter because we allow ourselves to change the focus of our minds, and that change in focus allows us to think more clearly about all the other things. When we are deeply involved in something (be it a hard problem or the daily matters of life) our perspective narrows and taking a break helps to open up our perspective – we get a new view on the world.

I have been able to take a long break from life and travel in the USA for a month. Travel always changes our perspective, and this trip gave me much to think about. Returning to my business and normal life probably gave me even more to think about. For the next while I will be focussed on some engineering design and process issues that I think can be improved upon, but I will continue to discuss the environment and how we and engineering interact with it.

For now, some thoughts on my USA trip:

- America has a throw away culture. Everything is paper, plastic and polystyrene and meant to dumped after using. Restaurants, coffee shops, rest rooms and homes – waste is everywhere. Americans generate far more waste than South African's do.

- I did not see energy saving bulbs anywhere (except my brother's house). Energy crisis? What energy crisis?

- When we see stats and numbers about waste and energy usage they are typically based on American studies. Due to the the above points it may not be fair to impose those numbers on South Africa. That means we need our own numbers, and our own measures. Using the US yardstick against ourselves will yield false results.

- We need to make sure we move towards a culture of efficiency, reuse and longevity – away from a culture of waste.

- It is hard to get a decent cappuccino. It is even harder to get it in a ceramic cup (I learnt to ask for a "to stay" cup on my last day).

- We need to learn how to be patient on the road. The Americans are really patient and courteous drivers. Most people's instant reaction would be that they have more policing. Is it more, or is it the style that matters? Also, do we really need to be policed to behave well?

- You can get just about anything you can think of (except a decent cappuccino).

- Nobody really knows or cares what happens in South Africa. We fool ourselves when we think our economic fortunes are closely tied to our political situation.

- South Africa has a soul, character and diversity which I am absolutely ecstatic to come home to.

Tuesday, August 12, 2008

9 simple ways to design for lower energy use

There are lots of really complicated and difficult ways to design for lower energy consumption, but most of us do not have the time or budget to do them. Yet, there are many really simple ways to reduce energy consumption which only take a few moments of our time. It is largely a matter of being conscience of the decisions we are making.

There are lots of really complicated and difficult ways to design for lower energy consumption, but most of us do not have the time or budget to do them. Yet, there are many really simple ways to reduce energy consumption which only take a few moments of our time. It is largely a matter of being conscience of the decisions we are making.Here are a few ideas:

- Use larger resistors

Does that pull–up/down resistor really have to be 1k? Could it be 10k or more? There are always engineering trade–offs to be made. Increasing resistor size increases noise and can make your design more susceptible to EMI, but there are many cases where resistor values can be increased with no discernable effect. Think about this, at 3.3V a 1k resistor will burn up 11mW, change that to 10k and the power consumption drops to 1mW. Your signal line should be in the correct default state (high for a pull–up and low for a pull–down) to ensure no energy is being spuriously expended.

- Turn off unnecessary LEDs

We (I) often use LEDs for debugging purposes, such as internally on an enclosed board. It helps us get some visual information about the system while debugging. Did you remember to turn those off in your release version? LEDs can consume a significant amount of power (1.5V @ 10mA = 15mW) which adds up for each LED that is needlessly left on.

- Dim or blink required LEDs

LEDs that provide visual information to the user can be dimmed or blinked to reduce power consumption. Try to determine whether those LEDs are really necessary in the first place – are there other indicators which are providing the same information? A laptop typically has a power LED and a screen which both provide feedback that it is on, while cellphones have no power indicator other than the screen. Does the laptop really need the power LED to be on all the time? What if it was only on when the screen was turned off, or flashing while in sleep mode? What if the battery indicator flashed when the laptop was off and the battery was full instead of being permanently on? How else can you convey the same information?

- Put microprocessors to sleep

Microprocessors are often waiting for an event such as a timer or communications interrupt. It is normally a simple task to put a device to sleep while it is idle. Some simple code can reduce the power consumption (and extend the battery life) of your device.

- Turn off unnecessary peripherals

Microprocessors usually have a number of peripherals which are either not used, or not used all the time. If unused peripherals are clocked that means that energy is being banished to heat just to clock something that is idle. Not all devices support this, but more and more are coming out with these features (such as the Luminary Micro range).

- Use low power components

Duh! That may seem obvious, but take some time to look at the quiescent current of the components you choose when designing. Faster components (like high speed op–amps) typically require more power when idle, while slower components require less. Consider using a slower op amp or lower power transceiver.

- Use a higher bus voltage

When you are running long wires (e.g. power bus around a warehouse) use the highest voltage that is practical. This will help reduce power loss due to copper losses. It also means you can use thinner cable, or run more units from a single cable (if cable current is a limiting factor).

- Use a lower bus voltage

Have you considered using a lower system voltage (e.g. 1.8V instead of 3.3V)? The limiting factor is often peripherals which require certain voltages, but you can consider other peripherals or use level translators. There are a lot of trade–offs to consider here, so use your engineering wisdom to come up with the best solution.

- Consider latching relays

Normal relays require a continuous current flow to keep them in the on position, while latching relays only require a short pulse to switch from one position to the next. You will have to consider cost and a small amount of extra circuitry, but these are particularly valuable where there are power supply limitations.

Photo courtesy of Windell H. Oskay, www.evilmadscientist.com

Wednesday, August 06, 2008

Fortune

Thank you for your continued support as readers of this blog. I appreciate your time and attention to read what I put down here, and to make thoughtful comments on it.

Monday, July 28, 2008

Volunteering to Die

We need three planets for everyone to live like the average European. In other words, if we continue on our current path two out of three people are going to die. In a world of more than six billion people, that is going to be an awful lot of pain.

We need three planets for everyone to live like the average European. In other words, if we continue on our current path two out of three people are going to die. In a world of more than six billion people, that is going to be an awful lot of pain.Will you be one of those who has to die? Your wife? Children? Friends?

So instead of carrying on along a path that will eventually end in heartache, I am going to choose a more difficult way.

I am volunteering to die.

This requires more than resolve and determination – this requires action. It means I have to push against the tide, to take some steps along a less trodden path.

Even though this may appear to be a great self–sacrifice, this is about creating a new life. A new life which enables each of us to have access to clean air, clean water, and nutritious food while nurturing our home (our planet) instead of sucking it dry. It is about acknowledging that we can all live a great life by learning how to live with just one planet, by cutting off and putting to death that part of us which lives like there are three (or more) planets. That is what I am volunteering to do.

The "good life" that has been sold to us is one where we take no responsibility for its consequences. It is a life that consumes with indifference and wastes without thought. Living like that is like extending your mortgage loan more and more each month, eventually the money runs dry and the bank manager comes to collect on the debt by taking your home away. I would rather figure out how to keep my home.

The exciting thing is that this is not about saving the Riverine Rabbit (even though that is important, because we are all connected) – this is about creating better, happier and more fulfilling lives. It is about climbing off the work–spend–work hamster wheel and finding satisfaction beyond the consumption of stuff.

Even though the "good life" we have been sold may be an illusion, putting that to death is a slow, complicated and sometimes painful process. The sooner we can do it though, the sooner we will be able to live a new revitalised life.

"Just as obesity is best overcome by adopting a nutritious, varied, tasty diet and a healthier lifestyle, so too our global overconsumption will be solved by moving to different – but better, healthier and happier – ways of living." – A One Planet Future (worth a read)Here are some ways to start right now.

Picture courtesty of the WWF One Planet Future campaign

Wednesday, July 09, 2008

Saying No

Saying No is an important part – a critical part – or our job as engineers and designers. Great products are designed by people who know when to say No and when to say Yes.

Great products do not need feature lists and check boxes. Great products are sold by their users because they love them.

You know what the most difficult thing about this is? You have to choose, and choosing means you have to be brave.

I just love this graph from Kathy Sierra and the article that goes with it (thanks for the inspiration).

"Give users what they actually want, not what they say they want. And whatever you do, don't give them new features just because your competitors have them!" – Kathy Sierra

Wednesday, July 02, 2008

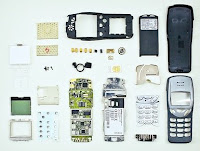

What Engineer Simplicity does

There are a lot of steps to turn an idea into a product. Each step requires care and attention to ensure that the best product is created. Below is the process that I follow to create an electronic product. It is all laid out nicely in a linear way, but in reality a lot of the steps are occurring in parallel. Also, any step could be the starting point, it is really dependant on the product and client requirements.

There are a lot of steps to turn an idea into a product. Each step requires care and attention to ensure that the best product is created. Below is the process that I follow to create an electronic product. It is all laid out nicely in a linear way, but in reality a lot of the steps are occurring in parallel. Also, any step could be the starting point, it is really dependant on the product and client requirements.- Initial engineering report

This is a short report which gives everyone some preliminary ideas to work from. I like to start with this as it is a small investment in testing the idea, and provides a lot of information for the path forward.

- Detailed investigation

The initial report or specification has already identified the options, now all the options are investigated in detail. This entails reading datasheets and application notes, speaking to distributors, and really understanding whether the available options will provide the required solution.

- Development of proof of concept

There are two ways to go here, either develop a proof of concept using evaluation boards, or dive straight into the custom hardware design – which is better depends on the risks involved. The risks are a function of the project and the amount of experience with similar designs. Wherever possible it is nicest to speed things up, but a detailed proof of concept can take a lot of risk out of the later stages.

- Final concept

After a full proof of concept it is quite clear how all the pieces fit together. At this stage we should have system block diagrams, communication protocols, component choices, disposal planning and a whole lot more down on paper. The framework for our creation is in place, now we need to make a real prototype.

- Schematic layout

All the concepts and ideas have to be put down into technical drawings (an electronic drawing is called a schematic). Once this is done we have a schematic, a BOM (bill of materials), and other technical files needed for the next steps.

- Printed circuit board layout

The schematic output is used to generate a printed circuit board (PCB layout). The physical size is determined and the components are placed and connected together with tracks. Any mechanical design which is required (e.g. a casing) is also done along side with this step so that the PCB will fit nicely. This can be a time consuming step, as a lot of checking is required, such as tolerances, spacing and component patterns. A set of gerber files are generated which are used to manufacture the actual PCBs.

- Component procurement

Before a prototype can be built, you need all the components that will be placed on the PCB. This step is really happening in parallel with all the other steps to ensure that everything arrives at the right time. Electronic component lead times can vary significantly (from 1 to 16 weeks or more), so a fair amount of planning and scheduling is required.

- Prototype manufacturing

A PCB manufacturer (such as WHCircuit or Trax) makes the PCB's according to the gerber files. The PCB is then populated with the components either by hand or machine. For a first prototype I like to populate the board by hand (where possible) so that I can test each part of the system as I build it up.

- Development and debugging

The amount of effort that goes into making a system work properly is really quite big, but depends on the complexity of the system and the amount of detail that went into all the proceeding steps. It must be shown that each block of the system works and that it all works together properly. Firmware (software that runs on the system) must be tested and developed to a fully functional level. Any bugs that are detected need to be resolved and noted for the future.

- Testing

Once all the functionality is working it must be fully tested, both to check that it is working correctly and to also stress the system to find out if any real world events could break things. Careful attention must be paid to test as many usage cases as possible, and more. Certain countries require specific certifications and any required tests must be done to ensure all the necessary specifications are met.

- Design refinements

All of the testing and development will either have proved that the design works exactly as desired, or indicated areas that need to be improved before going ahead with manufacturing. Steps 4 to 11 are repeated until the product meets the requirement.

- Initial production run

Manufacturing can bring its own challenges to the product from solderability through to the programming and testing of the product. To avoid major manufacturing disasters it is normally better to have a small initial run to iron out any problems in the process.

- Product manufacturing

Once all the manufacturing issues have been resolved it is time to go into full production. This can be a big investment and the quality of the work that has gone before will determine how successful the product is.

- Continuous improvements

There are always things to improve. Wherever possible I try to build in mechanisms that allow easy upgrading of products (such as in–field upgrading of firmware), but it is sometimes necessary to go through some redesign to meet a new requirement or fix a manufacturing issue. Once a product is out in the field you start to get a feel for how it is really used, which teaches you a lot about how to improve the quality.

If you are interested in creating electronic products, then please contact me.

Photo courtesty of Johannes Henseler and licensed under a Creative Commons license.

Monday, June 23, 2008

Sweat the small (and big) things

How we each approach this depends a lot on our personalities. Some people think big and need to see huge value resulting from their actions. Others find joy in fine tuning all the details and making sure that everything is just right.

I feel that the two go hand in hand. Each on its own lacks substance. If all you can see are the fine details it is difficult to work towards a bigger goal. If all you can see is the big goal, it is hard to see the small steps that need to be taken to achieve it. It is a bit like that saying: how do you eat and elephant? One bite at a time.

I feel that the two go hand in hand. Each on its own lacks substance. If all you can see are the fine details it is difficult to work towards a bigger goal. If all you can see is the big goal, it is hard to see the small steps that need to be taken to achieve it. It is a bit like that saying: how do you eat and elephant? One bite at a time.Setting big goals is important, and so is sweating the small stuff. We still come back to that question though: where should we focus our energy to have the largest impact?

There are two important areas to focus on,

- The biggest point of pain, and,

- The easiest thing we can do.

I am currently working on a warehouse floor application and one of the issues is power consumption. Power consumption affects how many units can be powered from a single power supply, and what type of cabling is used. When I made some measurements I found that the system was consuming way more energy while idle than I was happy with. The easiest (and in this case only) way to address that was to do some investigation into the power saving options of the microprocessor. I managed to cut the idle power consumption to 20% of what it was. In this case the amount of power saved per unit is not much (100mW) but the number of units is high. It helps me to increase the number of units I can drive, as well as saves a reasonable amount of energy overall. That small saving per unit will save around 350kWh/month in this application – the monthly energy consumption of my home.

So sweat the small stuff, and sweat the big stuff. Build momentum and keep moving forward.

To the engineers: what you do matters – keep making good choices.

Photo, courtesy of Mandy Goldberg, licensed under a Creative Commons license.

A quick guide to computer energy saving

- Set your monitor/display to turn off after 15 minutes or less (don't use a screen saver).

- Set your hard drives to turn off after 15 minutes or less.

- Set your system to sleep after 30 minutes or less.

- Choose "Minimal Power Management" as a power scheme in XP (this makes sure the processor can go into low power modes while it is not busy). In Vista make sure your "Minimum processor state" is set to a low value under the advanced power options and "Processor power management."

Tuesday, June 10, 2008

Leaving the lights on

I am an advocate of making sure that every device consumes as little power as possible at all times. Indicator lights should be off, processors should be sleeping as much as possible, and generally the device should just be optimised to use as little power as possible.

I am an advocate of making sure that every device consumes as little power as possible at all times. Indicator lights should be off, processors should be sleeping as much as possible, and generally the device should just be optimised to use as little power as possible.I may have to rethink that....at least a little bit.

Dan Lockton has a brilliant blog, Architectures of Control, where he discusses how things are designed to result in a certain action (or lack of action) – or as he calls it, design with intent.

There are two devices in my home which have helped me to reconsider turning off all the lights, my DVD player and my laptop. Each has its own subtle "architecture of control" whether intentional or not.

Our DVD player has (to me) the most irritating standby light that I have ever seen on any device. When on, the light is constantly illuminated, but when in standby the light flashes continuously (at a slow rate). This drives me mad, but results in an interesting action – it causes me to turn it off at the plug when I am not using it (which is most of the time). Suddenly one little flashing light has resulted in more energy saving than having no light.

My laptop has a similar "feature." When it is powered down the battery indicator remains on (green if full, flashing yellow if charging). This used to bother me, and I thought, "Why not just leave the light off when the battery is charged?" My wife's laptop is like that, the battery indicator only flashes if it is charging, once charged it turns off.

My laptop has a similar "feature." When it is powered down the battery indicator remains on (green if full, flashing yellow if charging). This used to bother me, and I thought, "Why not just leave the light off when the battery is charged?" My wife's laptop is like that, the battery indicator only flashes if it is charging, once charged it turns off.That is all good, except my laptop communicates to me that it is plugged in and consuming standby power when it is not in use. When I unplug it from the wall socket, then the battery indicator goes off – I save the standby power of both the power brick and the laptop.

There is one problem with this, it only works on people who care. If I did not care about saving energy, then I would just leave the laptop plugged in and the DVD player on. That means that you have to consider how your users will handle this kind of subtle feedback and determine whether turning the light off, or encouraging unplugging results in more energy savings.

Sometimes the most obvious design decisions may not be the ones which result in the greatest energy saving. Keep designing for low energy consumption and also keep your mind open to new possibilities.

Wednesday, June 04, 2008

Engineer Simplicity....

Your idea may be a new invention, a faster warehouse picking system, or a testing and debugging tool which makes your company run faster and better.

Bring it to me and together we will turn your idea into a great product.

Monday, June 02, 2008

Innovate for a better South Africa: SA Blook Chapter 10

So what is our reality?

So what is our reality?South Africa has an unemployment rate of about 23%, a skills shortage crisis, rising inflation, rising interest rates, a large current account deficit and an uncertain political environment – amongst a number of other things.

All of this points towards a great need, and with great need, comes a great crisis...just not the one you are thinking about. The great crisis we have is a crisis of opportunity. Wherever there is need, there is opportunity.

In this midst of this great opportunity the challenge that we face is finding people who are ready to create solutions. We must find and create people who are willing to innovate each day.

We are all innovators and have the ability to contribute to the creation of a better country. Unfortunately we tend to associate "innovation" with technological improvements, while it should really apply to every task that we do. Innovation needs to become a concept which permeates how we do business, and how we go about our jobs each day.

The other problem is that we tend to think of innovation as large leaps forward. Personally I prefer the Japanese concept of Kaizen, which means continuous change for the better (Mind of the Innovator is worth a read). So when I use the word innovate, I mean keep changing things for the better.

On its own, technical advances will only change South Africa a small amount. We need innovation to happen on all fronts – legal, government, business – but most importantly we need it to happen at a people level. We need to find ways to keep changing ourselves for the better, and with that the rest will come easily.

So how do we as businesses and individuals work towards a better South Africa?

- People matter

Our country, and our businesses run on people. The more we place value on each individual, the more value we build for ourselves. It is time to stop thinking about "human resources" and start thinking about people. People matter, and what they care about matters too.

We are connected to the people around us. Acting in the interest of those around us serves not only to build a better country, but also to nurture and secure our own future. - Engage in the discussion

We all need to engage in the discussion that is going on around us and try to contribute positively to it. Talking builds community and that forms the foundation for a better country. It helps us find out what matters to other people, and how we can help.

I have been fortunate enough to be a part of an amazing online business community, The Forum SA, which has brought various business owners and managers together to engage with each other. Together we help each other with the daily challenges of running a business. It also provides a platform for us to work together as a group to improve conditions for small business owners in South Africa. Together we create a better country.

The more we take part, the more we grow. Maybe it is time to grow together. - Be remarkable: make and do things that matter

Jim Collin's wrote, "Good is the enemy of great." Or in Seth Godin's words, be remarkable.

As a whole we have given up our greatness. We have lost our sense of greatness to crime, dirty politicians and corrupt businessmen. Yet as a country we are filled with greatness, even if we are not always able to recognise it.

What and how we do things changes our view of both ourselves and the people around us. Do your actions reflect who you want to become? Do they reflect the country you want to live in? Do they build your (our) greatness, or break it down?

What comes out of us, both in actions and words, reflects not only who we are, but who we are becoming. What steps did you take on the road to greatness today? We need to walk that path – one step at a time. - Do more with less

Right now we can all feel the pressures of inflation. There are two basic ways to combat inflation – consume less, or produce more. If we can do both at the same time it is a double win. Innovation can help us to both increase productivity as well as decrease costs.

As much as technological innovation can help, finding new ways to equip people with skills and increase their productivity can help even more. As we educate people through schools, universities and on–site training we grow our ability to deliver. As we produce and deliver more we push down inflation.

Each of us has the responsibility to help develop another person. Remember, people matter.

The thought that I would like to leave you with is a question that I have been asking myself quite a bit lately – what is your reality? Think about that for a second before answering. We get bombarded from all directions (media, government, business) by someone else's reality (or one they want us to believe). Too much of that starts to change the way we see our reality.

So, when we strip it all away, when we really look at the exact details of your life, it may be that things are a lot better than we have been led to believe. Spend some time thinking about it.

What is your reality? How can you keep changing it for the better?

Next chapter: The role of the younger generation in SA, and what we need to do to support them.

Previous chapter: Making the most of SA's creative talent and abilities.

This post is a chapter of the SA Blook: A Piece of Significance, an online book written by a diverse group of writers with strong views of our country and the reality we find ourselves living in. The other chapters in the Blook are here:

- The new South Africa - is it real?

- Is SA rich or poor?

- What the world thinks of South Africa and what our global opportunities are

- The importance of each individual's contribution collectively

- SA Inc and the business of doing business in SA

- The beauty and grandeur that surrounds us

- The importance of technology in SA's global emergence

- Building brand South Africa

- Making the most of SA's creative talents and abilities

- Innovate for a better South Africa

- The role of the younger generation in SA, and what we need to do to support them

- Connecting South Africa - Communities that transcend technology

- We are African - the role of collaboration in South Africa's growth

This post is licensed under the Creative Commons Attribution-Noncommercial-No Derivative Works 2.5 South Africa license.

The picture is used under stock.xchng's standard license and was taken by Lynette Lan.

Friday, May 30, 2008

Blook SA

Monday will see the release of The Blook SA. I am very honoured to have been asked to write a post for it, and I am looking forward to reading the whole thing. There are some really awesome people involved:

- Andy Hadfield

- Duncan Drennan

- Eve Dmochowska

- Grant Brewer

- Justin Hartman

- Kerry-Anne Gilowey

- Mandy de Waal

- Melissa Attree

- Nic Haralambous

- Paul Jacobson

- Saul Kropman

- Tycoon's Geoff Candy and Hilton Tarrant

- Siyabonga Nhlumayo - guest writer

Darren Gorton of Out-Think has been the organising force behind this. Here are all his Blook related posts, and the original idea.

See you on Monday when you come back to read the full Blook :)

Tuesday, May 20, 2008

Follow me on Google Reader (forget twitter)

Google Reader recently released a new feature which enables me to share some more of my thoughts with you.

Google Reader recently released a new feature which enables me to share some more of my thoughts with you.I have never been a big fan of regurgitating other people's post and information on my own blog. I see this more as a place to try to share my own thoughts and ideas, or bring a bunch of info together to express a new opinion (I hope I manage to!). So far I have been pointing to blog posts that have stood out to me via the "Interesting article's I've recently read" section in the side bar.

The links in the side bar are the most recent items I have shared using Google Reader. Up until recently, it was only possible to share things that I received via feeds (see below if you don't know what a feed or RSS is). What the clever guys over at Reader have now done is to allow me to share anything, from anywhere and add my own note to that.

This is a new form of microblogging, but is far more interesting (to me, and hopefully to you) than the alternatives, such as twitter.

So now you can follow me and see my thoughts on interesting articles and information that I find. There are a couple of ways to do this.

- Subscribe to my Google Shared Items feed. If you know how a feed reader works, you'll know exactly how to use that link to follow me. Otherwise, see the info about feeds and feedreaders below.

There are one or two minor drawbacks with this, mainly that the original author's name does not come through correctly when I add a note. - If you already use Google Reader you can add me as a friend and my shared items will show up in your Reader. This is a slightly more complex process and requires you inviting me to chat with you via Gmail or Gtalk. You will need my Gmail address, which is duncan.drennan at the expected ubiquitous domain name.

- [Update] As Francois quite correctly points out, you can also view my shared items as a webpage (which is linked to in the side bar).

Here is some info for those of you who have never heard of a feed or RSS. On this site subscribing to the feed allows you to immediately receive the latest posts straight into your feedreader.

A feedreader fetches information from a whole bunch of different feeds (e.g. this blog, a news website, etc.) displays them for you.

The beauty of this is that

- You can subscribe and unsubscribe extremely easily (just add or delete a feed from your feedreader).

- Delivery is guaranteed. Because you fetch the feed (pull) unlike email which is sent to you (push) the feed cannot get lost due to a firewall which is trying to stop spammers. Feeds are spam free!

- You never miss a post. This is particularly important if you keep up to date by coming to check back here regularly. You could miss something, or worse, stop coming back ;)

Monday, May 05, 2008

Facing the food crisis

The result of all of this deregulation meant that small producers lost access to the local market giving global market access to a few global producers. Three companies—Cargill, Archer Daniels Midland, and Bunge—control the vast majority of global grain trading, while Monsanto controls more than one-fifth of the global market in seeds. Consumers from Sioux City to Soweto are more and more dependent on fewer and fewer producers. By eliminating the breadth and diversity of the system, we’ve eliminated its ability to withstand shock or manipulation.

Perhaps the greatest evidence of the scale of deregulation of the world agricultural market is the liquidation of reliable grain reserves. Though we’ve impressively deregulated financial markets, the Federal Reserve and central bankers across the globe still maintain the ability to soften the spikes and plunges of our monetary system. Not so in food markets. For centuries grain reserves have been an essential component of functioning food systems. When prices are high grain reserves can be released on the market, bringing prices down. When prices are low, reserve systems buy up grain, bringing prices back up. In the last two decades, however, the U.S. and most other governments have let reserve systems wither, placing full faith in the free market to self-correct, and eliminating their last emergency response mechanism.

Read the full article on UrbanSprout. Also further reading.

I am no fan of biofuels (or bio–plastics), but I have been a little bit suspicious that all the fingers are being pointed at it as the main cause of the food crisis.

But, looking at this, this crisis is a much more complex and deadly beast. We have already seen the same thing playing out in South Africa in both our bread and diary industries.

Unlike money supply there is currently no way to normalise the fluctuations in food prices - so where to from here? What can we do to fend of this looming crisis?

Trevor Manuel has quite clearly indicated what he thinks is best - grow as much food as possible.

Manuel said food prices had broken out of a 150-year pricing band and shot up in relation to other living expenses. “I don’t think you are going to see a reduction in prices for some time, so whatever can be done to encourage people to plant on every piece of arable land would be a benefit to all,” he said.

I think a lot of people see that comment as a drive for subsistence farming. Yes, and no. In the face of rising food prices, producing food will be a profitable business, whether on a small or large scale. And that means that growing more food makes good business (and social) sense for South Africa.

On the other hand there is a strong case for backyard growing, as well as the conversion of water loving fields of grass to food producing gardens.

"Agriculture is becoming more and more suburban," says Roxanne Christensen, publisher of Spin-Farming LLC, a Philadelphia company started in 2005 that sells guides and holds seminars teaching a small-scale farming technique that involves selecting high-profit vegetables like kale, carrots and tomatoes to grow, and then quickly replacing crops to reap the most from plots smaller than an acre. "Land is very expensive in the country, so people are saying, 'why not just start growing in the backyard?' "

So maybe amongst all the turmoil there is a great opportunity. For some it may be a financial opportunity. For others (like me) it is an opportunity to have some fun (because growing stuff is cool) and contribute in a meaningful way to a number of issues facing us.

Will you be a victim or a hero of this crisis?

[2008/05/15 Update] Thanks to Pia for pointing out this article about the Western Cape making municipal land available for growing food.

Friday, April 25, 2008

The engineering design process

In some ways that is really as simple as it is.

Changing a problem into a solution is a wonderful and rewarding process. It is about creating more value in the world around us. I often ask myself, "How does doing this make the world a better place?" By being true to that I can create (and help you create) truly great products.

Monday, April 14, 2008

Creating a culture of reuse

Reuse is the forgotten R of the three R's.

Reuse is the forgotten R of the three R's.We currently have a materials chain that goes something like this: harvest resource, manufacture, distribute, use, dispose.

Recycling adds an extra step where things are collected during disposal and reintroduced into the manufacturing stage as raw materials. There are two things about recycling that need to be noted:

- Many materials are unsuitable to be recycled into the same thing. Plastics are probably the best example. They are either used to supplement the virgin (new) feedstock, or made into entirely different products (e.g. PET from drinking bottles is recycled into clothes, insulation, credit cards, etc.)

- Recycling often involves breaking down the product into something as close as possible to the original feedstock. This means that all the energy that went into it is lost. Glass is a good example.

The things that I have read about reuse have all been focussed on reusing items in the home and giving or selling them to other people who can use them (which are both important).

I want to see industry take responsibility and start collecting items for reuse, rather than recycling (wherever possible). We have seen this happening our whole lives: glass soda bottles. Every time you took a glass soda bottle back to the store and had your deposit paid back you were putting a bottle into the reuse chain.

The reuse chain works like this: instead of disposing of something it is taken back to the distributor (the store it was bought from). When the manufacturer makes deliveries they also collect the items for reuse. At the factory the items are inspected and cleaned. Any items that are unsuitable for reuse are recycled, and the rest is reused.

This means far less energy is expended on recycling and manufacturing new items which could have been reused. The easiest thing to imagine this working with is glass bottles and jars of any type, but why not expand this to everything? Why not start designing reuse into our products?

There would be huge savings for manufacturers, as they would not need to keep buying new materials. The only costs are the collection and logistics, which are already in place for the distribution of the product.

Packaging is a great example. If packaging can be made durable enough to be reused multiple times then consumers could just keep returning that packaging until it reached the end of its life cycle.

It does require a rethink of how we design, package and distribute things, but the benefits would be great for everyone – both manufacturers and consumers.

Wednesday, March 19, 2008

Engage in the discussion

"As meaningless as changing a CFL may be, the people that change the CFL bulbs get engaged in the discussion – and that's important." – Colin Bevan, aka No Impact Man

There seem to be a lot of people who challenge individual action. I have often found that those same people shift responsibility.

There seem to be a lot of people who challenge individual action. I have often found that those same people shift responsibility.I am sure you have heard it before:

- "What difference can I make? The government should..."

- "For every plastic bag you recycle, someone else throws ten away."

- "How does it help if I ride my bicycle to work while someone else drives their 4x4?"

I decided that it was time to start recycling as much of our waste as possible. I already had a compost heap which was taking care of any organic waste. Now it was time to deal with plastics, cardboard, paper and the likes. After dutifully sorting my plastic waste I went to the Morning Star dump expecting to be able to deposit my various recyclables. Well, things did not turn out quite as I would have hoped. There just did not seem to be the facilities that were advertised.

Being me I sent off an email to find out what was supposed to be happening. After some emails back–and–forth it seemed like things should be better. So off I went for my second attempt at recycling. This time things were organised and clear. Everything went into the proper recycling bins. I was pleased.

Third visit...unfortunately it was exactly like the first. No recycling bins. Confusion. So back to square one with another email sent off.

So what is the point of my story? My action (recycling) has got me engaged with a problem within my community. It has me engaged in a conversation around the problems and challenges that we face. Suddenly I care about the quality of the dump in my area. That one small action has changed me.

So I encourage you to take action. Just choose something you care about and start doing something. It may or may not change the world, but it will change you.

Wednesday, March 05, 2008

Degradable plastic

I recently bought some apples and spotted an intriguing little logo on the back of the plastic packaging. I look carefully at just about all plastic packaging these days in an attempt to identify what type of plastic it is (and therefore how recyclable).

I recently bought some apples and spotted an intriguing little logo on the back of the plastic packaging. I look carefully at just about all plastic packaging these days in an attempt to identify what type of plastic it is (and therefore how recyclable).What I found was a bit different to what I was expecting. Below a little logo was a website reference, www.degradable.net. So, off to the website to find out what this was all about.

It turns out that these smart guys have developed a low cost additive for polyethylene and polypropylene which causes the plastic to break down into a biodegradable form (the long plastic chains break down into shorter chains which can then be accessed by micro organisms which break them down to carbon dioxide and water. You can read the full details on their site). Astrapak are the South African suppliers of these plastics. There are also some alternatives to the d2w process which make use of light sensitive, or starch additives.

The great benefit of this is that plastics which are disposed degrade much faster (they can be set to degrade after 60 days or up to 6 years later). One of the issues that this technique creates is that it impacts on recycling. The degradable plastic can be recycled, but in their words, "..there are many different and complex permutations of both input feedstock and output materials which need to be individually considered," i.e. it's complicated. It seems like it is easier to create recycled material that is degradable, while creating non–degradable recycled products is trickier.

The great benefit of this is that plastics which are disposed degrade much faster (they can be set to degrade after 60 days or up to 6 years later). One of the issues that this technique creates is that it impacts on recycling. The degradable plastic can be recycled, but in their words, "..there are many different and complex permutations of both input feedstock and output materials which need to be individually considered," i.e. it's complicated. It seems like it is easier to create recycled material that is degradable, while creating non–degradable recycled products is trickier.This seems like a big disadvantage, but according to the EIA only 5% of plastics produced in America are recycled (I am sure that figure is much lower for South Africa). That means that up to 95% of the plastic produced ends up in land fills, water ways and generally strewn around the country side. At least using degradable plastics means that they will have a smaller, and shorter impact on our environment.

I am sure that a lot of people would rather argue the case for bioplastics. Personally I have always been sceptical of the benefits of bioplastics (and biofuels), mainly due to the pressure they place on food prices. More recently there have been some studies revealing that biofuels may damage the environment more [1][2] than emissions due to conventional fuels (bioplastics come from the same process, and therefore have a similar impact). So bioplastics may not currently have all the benefits that they claim.

I am sure that a lot of people would rather argue the case for bioplastics. Personally I have always been sceptical of the benefits of bioplastics (and biofuels), mainly due to the pressure they place on food prices. More recently there have been some studies revealing that biofuels may damage the environment more [1][2] than emissions due to conventional fuels (bioplastics come from the same process, and therefore have a similar impact). So bioplastics may not currently have all the benefits that they claim.Degradable plastic is a great product due to its reduced impact on the environment, but we do need to examine how we use and dispose of plastics. The reality is that plastic feedstock (oil) is a limited resource [3] and we need to use it wisely. Biofuels and bioplastics may not be the panacea that many people have hoped for. Only a small percentage of plastics are recycled. Plastics that are recycled are typically used to make other products rather than replace the recycled product, which means virgin feedstock is constantly required.

The real long terms solution is to reduce the amount of plastic we use, as well as reuse it as much as possible, and to continue recycling when a product reaches the end of its lifetime. So, in my mind, the question is this: how do we create plastic products with longer lifetimes? That is what really needs to change.

References:

[1] "Use of U.S. Croplands for Biofuels Increases Greenhouse Gases Through Emissions from Land Use Change" by Timothy Searchinger, et al.

[2] More on the negative impacts of biofuels.

[3] According to Waste Watch,

"It is estimated that 4% of the world's annual oil production is used as a feedstock for plastics production and an additional 3-4% during manufacture."

Search This Blog

Subscribe

Tags

About this blog

I'm Duncan Drennan and this blog is about spreading ideas regarding engineering, our environment and creating a better world. You can also follow me on Google Reader.

About Engineer Simplicity

Engineer Simplicity specialises in the design and development of electronic products.

Copyright Notice

Popular Posts

-

We are in the middle of an energy crisis and each of us need to make some dramatic changes to ensure that we have electricity, and that the ...

-

As engineers we spend a lot of time solving problems. A customer has a problem and it needs to be fixed. The electronic boards you have just...

-

The short version (my "elevator pitch"): Compact fluorescent lamps (CFLs) use about a fifth of the energy of a normal (incandescen...

-

eWaste is a particularly difficult issue to deal with as it contains many different materials and lots of extremely hazardous substances. I...

-

With 48 post over nearly three years, I am certainly not a prolific blog writer. My goal has never been to write a lot, but to rather explor...

-

I am an advocate of making sure that every device consumes as little power as possible at all times. Indicator lights should be off, process...

-

So here we are, the first blog post...well, really, here I am. My name is Duncan Drennan and this is my blog on business, design, electronic...

-

Mercury in compact fluorescent tubes (CFLs) is a health hazard and therefore we should not use CFLs....at least that is the false message b...

-

We have allowed ourselves to be framed as consumers. We hear it constantly – we are not referred to as people, or producers, or savers, we a...

-

Electronic design automation tools like OrCAD , PADS and Altium Designer are part of an electronic engineer's day–to–day life. We need...

© The Art of Engineering 2013 . Powered by Bootstrap , Blogger templates and RWD Testing Tool