Monday, July 28, 2008

Volunteering to Die

We need three planets for everyone to live like the average European. In other words, if we continue on our current path two out of three people are going to die. In a world of more than six billion people, that is going to be an awful lot of pain.

We need three planets for everyone to live like the average European. In other words, if we continue on our current path two out of three people are going to die. In a world of more than six billion people, that is going to be an awful lot of pain.Will you be one of those who has to die? Your wife? Children? Friends?

So instead of carrying on along a path that will eventually end in heartache, I am going to choose a more difficult way.

I am volunteering to die.

This requires more than resolve and determination – this requires action. It means I have to push against the tide, to take some steps along a less trodden path.

Even though this may appear to be a great self–sacrifice, this is about creating a new life. A new life which enables each of us to have access to clean air, clean water, and nutritious food while nurturing our home (our planet) instead of sucking it dry. It is about acknowledging that we can all live a great life by learning how to live with just one planet, by cutting off and putting to death that part of us which lives like there are three (or more) planets. That is what I am volunteering to do.

The "good life" that has been sold to us is one where we take no responsibility for its consequences. It is a life that consumes with indifference and wastes without thought. Living like that is like extending your mortgage loan more and more each month, eventually the money runs dry and the bank manager comes to collect on the debt by taking your home away. I would rather figure out how to keep my home.

The exciting thing is that this is not about saving the Riverine Rabbit (even though that is important, because we are all connected) – this is about creating better, happier and more fulfilling lives. It is about climbing off the work–spend–work hamster wheel and finding satisfaction beyond the consumption of stuff.

Even though the "good life" we have been sold may be an illusion, putting that to death is a slow, complicated and sometimes painful process. The sooner we can do it though, the sooner we will be able to live a new revitalised life.

"Just as obesity is best overcome by adopting a nutritious, varied, tasty diet and a healthier lifestyle, so too our global overconsumption will be solved by moving to different – but better, healthier and happier – ways of living." – A One Planet Future (worth a read)Here are some ways to start right now.

Picture courtesty of the WWF One Planet Future campaign

Wednesday, July 09, 2008

Saying No

Saying No is an important part – a critical part – or our job as engineers and designers. Great products are designed by people who know when to say No and when to say Yes.

Great products do not need feature lists and check boxes. Great products are sold by their users because they love them.

You know what the most difficult thing about this is? You have to choose, and choosing means you have to be brave.

I just love this graph from Kathy Sierra and the article that goes with it (thanks for the inspiration).

"Give users what they actually want, not what they say they want. And whatever you do, don't give them new features just because your competitors have them!" – Kathy Sierra

Wednesday, July 02, 2008

What Engineer Simplicity does

There are a lot of steps to turn an idea into a product. Each step requires care and attention to ensure that the best product is created. Below is the process that I follow to create an electronic product. It is all laid out nicely in a linear way, but in reality a lot of the steps are occurring in parallel. Also, any step could be the starting point, it is really dependant on the product and client requirements.

There are a lot of steps to turn an idea into a product. Each step requires care and attention to ensure that the best product is created. Below is the process that I follow to create an electronic product. It is all laid out nicely in a linear way, but in reality a lot of the steps are occurring in parallel. Also, any step could be the starting point, it is really dependant on the product and client requirements.- Initial engineering report

This is a short report which gives everyone some preliminary ideas to work from. I like to start with this as it is a small investment in testing the idea, and provides a lot of information for the path forward.

- Detailed investigation

The initial report or specification has already identified the options, now all the options are investigated in detail. This entails reading datasheets and application notes, speaking to distributors, and really understanding whether the available options will provide the required solution.

- Development of proof of concept

There are two ways to go here, either develop a proof of concept using evaluation boards, or dive straight into the custom hardware design – which is better depends on the risks involved. The risks are a function of the project and the amount of experience with similar designs. Wherever possible it is nicest to speed things up, but a detailed proof of concept can take a lot of risk out of the later stages.

- Final concept

After a full proof of concept it is quite clear how all the pieces fit together. At this stage we should have system block diagrams, communication protocols, component choices, disposal planning and a whole lot more down on paper. The framework for our creation is in place, now we need to make a real prototype.

- Schematic layout

All the concepts and ideas have to be put down into technical drawings (an electronic drawing is called a schematic). Once this is done we have a schematic, a BOM (bill of materials), and other technical files needed for the next steps.

- Printed circuit board layout

The schematic output is used to generate a printed circuit board (PCB layout). The physical size is determined and the components are placed and connected together with tracks. Any mechanical design which is required (e.g. a casing) is also done along side with this step so that the PCB will fit nicely. This can be a time consuming step, as a lot of checking is required, such as tolerances, spacing and component patterns. A set of gerber files are generated which are used to manufacture the actual PCBs.

- Component procurement

Before a prototype can be built, you need all the components that will be placed on the PCB. This step is really happening in parallel with all the other steps to ensure that everything arrives at the right time. Electronic component lead times can vary significantly (from 1 to 16 weeks or more), so a fair amount of planning and scheduling is required.

- Prototype manufacturing

A PCB manufacturer (such as WHCircuit or Trax) makes the PCB's according to the gerber files. The PCB is then populated with the components either by hand or machine. For a first prototype I like to populate the board by hand (where possible) so that I can test each part of the system as I build it up.

- Development and debugging

The amount of effort that goes into making a system work properly is really quite big, but depends on the complexity of the system and the amount of detail that went into all the proceeding steps. It must be shown that each block of the system works and that it all works together properly. Firmware (software that runs on the system) must be tested and developed to a fully functional level. Any bugs that are detected need to be resolved and noted for the future.

- Testing

Once all the functionality is working it must be fully tested, both to check that it is working correctly and to also stress the system to find out if any real world events could break things. Careful attention must be paid to test as many usage cases as possible, and more. Certain countries require specific certifications and any required tests must be done to ensure all the necessary specifications are met.

- Design refinements

All of the testing and development will either have proved that the design works exactly as desired, or indicated areas that need to be improved before going ahead with manufacturing. Steps 4 to 11 are repeated until the product meets the requirement.

- Initial production run

Manufacturing can bring its own challenges to the product from solderability through to the programming and testing of the product. To avoid major manufacturing disasters it is normally better to have a small initial run to iron out any problems in the process.

- Product manufacturing

Once all the manufacturing issues have been resolved it is time to go into full production. This can be a big investment and the quality of the work that has gone before will determine how successful the product is.

- Continuous improvements

There are always things to improve. Wherever possible I try to build in mechanisms that allow easy upgrading of products (such as in–field upgrading of firmware), but it is sometimes necessary to go through some redesign to meet a new requirement or fix a manufacturing issue. Once a product is out in the field you start to get a feel for how it is really used, which teaches you a lot about how to improve the quality.

If you are interested in creating electronic products, then please contact me.

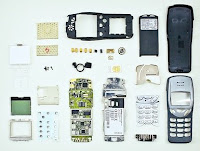

Photo courtesty of Johannes Henseler and licensed under a Creative Commons license.

Search This Blog

Subscribe

Tags

About this blog

I'm Duncan Drennan and this blog is about spreading ideas regarding engineering, our environment and creating a better world. You can also follow me on Google Reader.

About Engineer Simplicity

Engineer Simplicity specialises in the design and development of electronic products.

Copyright Notice

Popular Posts

-

The short version (my "elevator pitch"): Compact fluorescent lamps (CFLs) use about a fifth of the energy of a normal (incandescen...

-

As engineers we spend a lot of time solving problems. A customer has a problem and it needs to be fixed. The electronic boards you have just...

-

We are in the middle of an energy crisis and each of us need to make some dramatic changes to ensure that we have electricity, and that the ...

-

So here we are, the first blog post...well, really, here I am. My name is Duncan Drennan and this is my blog on business, design, electronic...

-

eWaste is a particularly difficult issue to deal with as it contains many different materials and lots of extremely hazardous substances. I...

-

There are a lot of steps to turn an idea into a product. Each step requires care and attention to ensure that the best product is created. B...

-

On 29 June 2009 my wife and I became parents to Grace Drennan. It is a great privilege, honour and responsibility to be a part of this amazi...

-

When James Bond used miniature cameras in the 60's and 70's the thought of a wireless phone that can take pictures and send them t...

-

Urban agriculture (UA) – the production of food within a city – is an important aspect of securing our food supply as well as restoring our...

-

This post forms a part of the SA Blook . So what is our reality? South Africa has an unemployment rate of about 23%, a skills shortage crisi...

© The Art of Engineering 2013 . Powered by Bootstrap , Blogger templates and RWD Testing Tool