Thursday, April 30, 2009

A slightly different direction

With 48 post over nearly three years, I am certainly not a prolific blog writer. My goal has never been to write a lot, but to rather explore issues from new angles and stimulate thinking and hopefully action. The positive side–effect of this has been exposure for my business, which was part of the original goal. In reality this blog has developed into much more than a marketing tool – it has become a platform for me to spread and amplify ideas, ideas which hopefully help to make the world a better place to live in.

With 48 post over nearly three years, I am certainly not a prolific blog writer. My goal has never been to write a lot, but to rather explore issues from new angles and stimulate thinking and hopefully action. The positive side–effect of this has been exposure for my business, which was part of the original goal. In reality this blog has developed into much more than a marketing tool – it has become a platform for me to spread and amplify ideas, ideas which hopefully help to make the world a better place to live in.Looking back over the titles of the blog posts there is a mix of mostly environmental issues and engineering. I have been spending a lot of time thinking about the direction of my own life, as well as of this blog. There is a definite changing of season for me – a new and renewed direction and energy – and with that comes a slight change of direction for this blog.

That change of season has a lot to do with making a shift towards more "doing" and less talking. I have noticed that I draw the most inspiration from people who actually do (or try to do) important and interesting things, from David's fuel–to–electric vehicle conversion to a friend who helps get blankets to babies living in cold tin shacks.

For me that means spending more time doing some of the things I have talked about or had on my mind for a while (like developing some systems to speed up my design process), as well as engaging with organisations that are doing things that I believe are important (like this urban agriculture group).

This means that there will be a slight shift of focus in the writing here. There will be a stronger focus on how I am developing my company and design process, and I will try to open up as many of the inner workings as possible so that everyone can learn from what I am doing (and hopefully not make the same mistakes!) Even though the focus will change a bit, there will always be a strong environmental slant, as creating a cleaner and healthier place to live is important to me and a part of who I am.

For the foreseeable future my commitment to you is to write one blog post every two weeks.

Thank you for coming on this journey with me. I am glad to have you along, and would love to hear from you (and thanks to all of you who have contacted me).

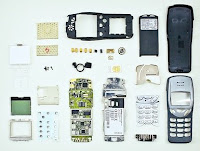

Image courtesy of Colin, licensed under a creative commons license.

Tuesday, February 03, 2009

7 rules for quoting

- Always give a quote

An offer is on the table ensures that you are in the running. Set a time frame for the quote and deliver on your commitment. This the first opportunity you have to demonstrate that you can deliver – make sure that you do. I recently quoted on a project and was shocked that at least three other companies had not bothered to deliver a quote.

- Know your worth

Understand your own value and how that contributes to the project. Undervaluing yourself leads to difficult financial situations and lack of motivation. Overvaluing results in a begrudging client who is unlikely to use you again. Clearly communicate the value that you add.

- Quote on fair value, not customer worth

Big customers may have more financial backing, but should not have to pay a premium for your services. You may want to under–quote a small customer to make sure that you secure the work. Everybody loses when a quote is not fairly valued. Under quoting undermines the project and compromises your ability to deliver a high quality end–product. Over quoting undermines your relationship with the client and damages future opportunities.

- Know your strengths and weaknesses

Understanding yourself will help you to leverage your strengths and compensate for your weaknesses. Quote around your strengths and approach the project in a way that gives you and your client an advantage over your competitors.

- Take reasonable risks

If we only quote for things that are comfortable we limit our ability to grow. Sometimes a project might seem too big, or require skills that we have not yet aquired. Push yourself enough that each project forces you to grow.

- Only quote if you can deliver

If you can't deliver or you are not the best option, then be open and clear about this. Your client will be happy to know that you did not mess them around. Doing work for work sake is a bad strategy.

- Be remarkable

Amplify your strengths and offer something remarkable. Remarkable could be the way you communicate with your client, the quality of your work, or the speed at which you are able to deliver it. It may even be the price (high can also be remarkable). Remarkable beats boring.

If you have an idea for a product, or a problem that can be solved electronically, then please contact me – I would love the opportunity to give you a quote.

Monday, October 06, 2008

Information duplication is the enemy of efficient systems

The electronic design process is made up of different parts such as schematic capture, PCB layout, component procurement and assembly. Each step requires information to be passed backwards and forwards. Certain information is only relevant to particular steps, for example you only need the exact part number for ordering, while a more basic part number or description could be used in the schematic (passives like resistors and capacitors are a good example of this).

Deciding what is important amongst all this information can be difficult, which often results in much of the information being duplicated in each step. The tools we use for electronic design automation (EDA) can inadvertently encourage us to create duplicate parts with detailed information contained within them. This seems fine until the parts library grows to an unmanageable size and discrepancies start to creep in, resulting in design and manufacturing errors.

Passing information between different systems, like the stock management and design systems can create an even larger mess. Typically these two systems are separated from each other and keeping them synchronised becomes a full time job. Any discrepancies between the two systems result in expensive time losses due to incorrect stock. The more information there is to keep track of, the greater the chance of errors and wasted time and money.

I am sure that most engineers have at some point in their career come across massive stock and bill of material spreadsheets which are overwhelming to manage, not just due to the amount of information, but also due to the incorrect tool (a spreadsheet) being used.

Yes, there are probably comprehensive ERP systems that can help with these problems, but those are not necessarily accessible to small engineering firms or individuals.

Information duplication is the enemy of efficient systems, we must eliminate it wherever possible.

That is the first rule of the process that I am developing for my own business. It will help me to develop faster and better, and once it is working it is going to allow every engineer access to the same opportunities.

Wednesday, July 02, 2008

What Engineer Simplicity does

There are a lot of steps to turn an idea into a product. Each step requires care and attention to ensure that the best product is created. Below is the process that I follow to create an electronic product. It is all laid out nicely in a linear way, but in reality a lot of the steps are occurring in parallel. Also, any step could be the starting point, it is really dependant on the product and client requirements.

There are a lot of steps to turn an idea into a product. Each step requires care and attention to ensure that the best product is created. Below is the process that I follow to create an electronic product. It is all laid out nicely in a linear way, but in reality a lot of the steps are occurring in parallel. Also, any step could be the starting point, it is really dependant on the product and client requirements.- Initial engineering report

This is a short report which gives everyone some preliminary ideas to work from. I like to start with this as it is a small investment in testing the idea, and provides a lot of information for the path forward.

- Detailed investigation

The initial report or specification has already identified the options, now all the options are investigated in detail. This entails reading datasheets and application notes, speaking to distributors, and really understanding whether the available options will provide the required solution.

- Development of proof of concept

There are two ways to go here, either develop a proof of concept using evaluation boards, or dive straight into the custom hardware design – which is better depends on the risks involved. The risks are a function of the project and the amount of experience with similar designs. Wherever possible it is nicest to speed things up, but a detailed proof of concept can take a lot of risk out of the later stages.

- Final concept

After a full proof of concept it is quite clear how all the pieces fit together. At this stage we should have system block diagrams, communication protocols, component choices, disposal planning and a whole lot more down on paper. The framework for our creation is in place, now we need to make a real prototype.

- Schematic layout

All the concepts and ideas have to be put down into technical drawings (an electronic drawing is called a schematic). Once this is done we have a schematic, a BOM (bill of materials), and other technical files needed for the next steps.

- Printed circuit board layout

The schematic output is used to generate a printed circuit board (PCB layout). The physical size is determined and the components are placed and connected together with tracks. Any mechanical design which is required (e.g. a casing) is also done along side with this step so that the PCB will fit nicely. This can be a time consuming step, as a lot of checking is required, such as tolerances, spacing and component patterns. A set of gerber files are generated which are used to manufacture the actual PCBs.

- Component procurement

Before a prototype can be built, you need all the components that will be placed on the PCB. This step is really happening in parallel with all the other steps to ensure that everything arrives at the right time. Electronic component lead times can vary significantly (from 1 to 16 weeks or more), so a fair amount of planning and scheduling is required.

- Prototype manufacturing

A PCB manufacturer (such as WHCircuit or Trax) makes the PCB's according to the gerber files. The PCB is then populated with the components either by hand or machine. For a first prototype I like to populate the board by hand (where possible) so that I can test each part of the system as I build it up.

- Development and debugging

The amount of effort that goes into making a system work properly is really quite big, but depends on the complexity of the system and the amount of detail that went into all the proceeding steps. It must be shown that each block of the system works and that it all works together properly. Firmware (software that runs on the system) must be tested and developed to a fully functional level. Any bugs that are detected need to be resolved and noted for the future.

- Testing

Once all the functionality is working it must be fully tested, both to check that it is working correctly and to also stress the system to find out if any real world events could break things. Careful attention must be paid to test as many usage cases as possible, and more. Certain countries require specific certifications and any required tests must be done to ensure all the necessary specifications are met.

- Design refinements

All of the testing and development will either have proved that the design works exactly as desired, or indicated areas that need to be improved before going ahead with manufacturing. Steps 4 to 11 are repeated until the product meets the requirement.

- Initial production run

Manufacturing can bring its own challenges to the product from solderability through to the programming and testing of the product. To avoid major manufacturing disasters it is normally better to have a small initial run to iron out any problems in the process.

- Product manufacturing

Once all the manufacturing issues have been resolved it is time to go into full production. This can be a big investment and the quality of the work that has gone before will determine how successful the product is.

- Continuous improvements

There are always things to improve. Wherever possible I try to build in mechanisms that allow easy upgrading of products (such as in–field upgrading of firmware), but it is sometimes necessary to go through some redesign to meet a new requirement or fix a manufacturing issue. Once a product is out in the field you start to get a feel for how it is really used, which teaches you a lot about how to improve the quality.

If you are interested in creating electronic products, then please contact me.

Photo courtesty of Johannes Henseler and licensed under a Creative Commons license.

Wednesday, June 04, 2008

Engineer Simplicity....

Your idea may be a new invention, a faster warehouse picking system, or a testing and debugging tool which makes your company run faster and better.

Bring it to me and together we will turn your idea into a great product.

Tuesday, May 20, 2008

Follow me on Google Reader (forget twitter)

Google Reader recently released a new feature which enables me to share some more of my thoughts with you.

Google Reader recently released a new feature which enables me to share some more of my thoughts with you.I have never been a big fan of regurgitating other people's post and information on my own blog. I see this more as a place to try to share my own thoughts and ideas, or bring a bunch of info together to express a new opinion (I hope I manage to!). So far I have been pointing to blog posts that have stood out to me via the "Interesting article's I've recently read" section in the side bar.

The links in the side bar are the most recent items I have shared using Google Reader. Up until recently, it was only possible to share things that I received via feeds (see below if you don't know what a feed or RSS is). What the clever guys over at Reader have now done is to allow me to share anything, from anywhere and add my own note to that.

This is a new form of microblogging, but is far more interesting (to me, and hopefully to you) than the alternatives, such as twitter.

So now you can follow me and see my thoughts on interesting articles and information that I find. There are a couple of ways to do this.

- Subscribe to my Google Shared Items feed. If you know how a feed reader works, you'll know exactly how to use that link to follow me. Otherwise, see the info about feeds and feedreaders below.

There are one or two minor drawbacks with this, mainly that the original author's name does not come through correctly when I add a note. - If you already use Google Reader you can add me as a friend and my shared items will show up in your Reader. This is a slightly more complex process and requires you inviting me to chat with you via Gmail or Gtalk. You will need my Gmail address, which is duncan.drennan at the expected ubiquitous domain name.

- [Update] As Francois quite correctly points out, you can also view my shared items as a webpage (which is linked to in the side bar).

Here is some info for those of you who have never heard of a feed or RSS. On this site subscribing to the feed allows you to immediately receive the latest posts straight into your feedreader.

A feedreader fetches information from a whole bunch of different feeds (e.g. this blog, a news website, etc.) displays them for you.

The beauty of this is that

- You can subscribe and unsubscribe extremely easily (just add or delete a feed from your feedreader).

- Delivery is guaranteed. Because you fetch the feed (pull) unlike email which is sent to you (push) the feed cannot get lost due to a firewall which is trying to stop spammers. Feeds are spam free!

- You never miss a post. This is particularly important if you keep up to date by coming to check back here regularly. You could miss something, or worse, stop coming back ;)

Thursday, March 01, 2007

Special thanks go out to Paul Jacobson for his Featured Business of the Week post on Engineer Simplicity, on BizTips (solo and small business tips and ideas). Paul, it is a wonderful experience to see other people talking about my business.

Special thanks go out to Paul Jacobson for his Featured Business of the Week post on Engineer Simplicity, on BizTips (solo and small business tips and ideas). Paul, it is a wonderful experience to see other people talking about my business.For those of you who would like to see your business featured, send Paul some interesting information about your business!

Paul is an attorney who runs Jacobson Attorneys in Johannesburg, and writes their blog. He is also an avid blogger (with numerous other blogs), and new media evangelist.

Technorati tags : marketing, engineer simplicity, chillibean, new+media, paul jacobson,

Tuesday, January 23, 2007

Modifying controls for a BMW R1200GS motorcycle

|

| The BMW R1200GS motorcycle |

Kobus has been creative enough to overcome all the obstacles to riding so that he can really enjoy his passion. He has modified the left handle bar so that a prosthesis (which he makes himself) can attach to it, and moved the clutch to the right handle bar.

|  |

| Modified left handle bar | Modified right handle bar |

So the next problem he needed to address was the riders controls, such as the indicators and horn. Here are some stock photos of the right and left handle bar controls for the R1200GS from BMW (the bike Kobus rides).

|  |

| Left hand controls | Right hand controls |

As you can see the left indictor, horn, brights/dim, ABS and Trip function buttons are all situated on the left handle bar, making them difficult for Kobus to access while riding (and slightly dangerous too!) - and that is where I come into the picture.

The first thing that I needed to do was analyse what the constraints of the motor bike were so that that I could decide on a plan of attack.

Kobus did his research when he went about choosing which motor bike to buy. The electrical system R1200GS runs on a CAN bus and there is a controller that performs all the functions. This means that it is relatively easy to achieve the required actions by stimulating the inputs of the controller, or in other words, we can trick the controller into thinking that one of the rider controls has been pushed.

The next step was to decide on how Kobus interfaced with the system - in the end we decided to do it like this,

| Sequence | Action |

| Right indicator: single click | Right indicator |

| Right indicator: double click | Left indicator |

| Right indicator: push and hold | Horn (until released) |

| Indicator cancel: single click | Brights/dim toggle |

In retrospect we made a mistake by not keeping the indicator cancel as its normal function and then using a double click for the brights/dim toggle. The indicator cancel has an auto cancellation, but it only occurs after a certain distance which can sometimes cause confusion when driving in urban areas. Other than that small oversight the controls turned out to work quite well with this method.

From there on it was all implementation, construction, and debugging.

I managed to find the wiring diagrams r1200gs.info. The switch configuration is relatively simple as each switch simply pulls one of the controller inputs down to ground to activate its function. The final solution was a simple microcontroller to time the inputs from the right hand controls and to switch the controller outputs based on the depression sequence of the controls. I had some trouble with the microcontroller acting a bit erratically when the motor bike was on, but that was solved by making the code more robust to erroneous inputs.

Kobus had this to say about the final system,

"Hi Duncan,

Just a word of thanks for the construction and programming of the control unit for my bike. It makes a world of difference being able to control my electrical systems by one hand. The upgrade made all the difference and the feel of the controls is excellent.

Again, thanks for some fantastic service.

- Kobus"

|

| Kobus taking a ride |

I hope that this brief description of a simple project will give you some more insight into what I do (and can do), and how I go about approaching it. I really want the things that I create to serve their user, not the other way around.

Creating simple interfaces and building a better life for my users is the most important aspect of my designs. I hope that I'll be able to do that for you some time soon.

Thanks to Kobus for the photos of his bike, H Marc Lewis for providing the great website r1200gs.info and Hex Microsystems (check out their GS-911 diagnostic tool for BMW motorcycles)

Sunday, July 30, 2006

A bit about me

Just a bit of background information on me....

I was born on 6 August 1979 and grew up in Port Elizabeth (South Africa). After school I went on to study electrical and electronic engineering at the University of Stellenbosch. I obtained my undergraduate degree Cum Laude and began my Masters degree directly after that.

My thesis was the design of a transverse flux machine - a high torque density machine (i.e. small, but with lots of va-va-voom). I studied under Prof. Maarten Kamper in the Electrical Machines Research group. After a year of full time postgraduate study I got married (to a very beautiful girl) and moved up to Pretoria. I continued working on my Masters degree until obtaining it in April 2005.

While in Pretoria I worked at Mecalc designing the front end of the MODACS system (low noise analogue design with a good dose of microcontrollers and FPGAs). I was there for just over three years until I decided to start Engineer Simplicity, so we moved to Cape Town and I have been running the company for over two years now.

Running my company has been an interesting, exciting and challenging experience. I have met and worked with some great people, and expanded both my skill and capacity to deliver exciting solutions. I have also slowly come to realise what is really important to me. As I blogged I found myself being drawn more and more strongly toward issues such as energy efficiency (which I have always been interested in) and waste management.

I discovered that what is important to me is to create products that help us move towards a cleaner and better world. So my focus is to find ways to create better products – products that make us happy and are sensitive to the world we live in.

I write about various things in this blog, from environmental issues through to engineering design. My goal is to explore these issues from an engineering perspective. Hopefully this inspires engineers to build a better cleaner world, and exposes people to new thoughts and ideas on how to create a better life right now.

I am glad to have you on this journey with me.

Search This Blog

Subscribe

Tags

About this blog

I'm Duncan Drennan and this blog is about spreading ideas regarding engineering, our environment and creating a better world. You can also follow me on Google Reader.

About Engineer Simplicity

Engineer Simplicity specialises in the design and development of electronic products.

Copyright Notice

Popular Posts

-

As engineers we spend a lot of time solving problems. A customer has a problem and it needs to be fixed. The electronic boards you have just...

-

The short version (my "elevator pitch"): Compact fluorescent lamps (CFLs) use about a fifth of the energy of a normal (incandescen...

-

We are in the middle of an energy crisis and each of us need to make some dramatic changes to ensure that we have electricity, and that the ...

-

eWaste is a particularly difficult issue to deal with as it contains many different materials and lots of extremely hazardous substances. I...

-

So here we are, the first blog post...well, really, here I am. My name is Duncan Drennan and this is my blog on business, design, electronic...

-

There are a lot of steps to turn an idea into a product. Each step requires care and attention to ensure that the best product is created. B...

-

With 48 post over nearly three years, I am certainly not a prolific blog writer. My goal has never been to write a lot, but to rather explor...

-

When James Bond used miniature cameras in the 60's and 70's the thought of a wireless phone that can take pictures and send them t...

-

On 29 June 2009 my wife and I became parents to Grace Drennan. It is a great privilege, honour and responsibility to be a part of this amazi...

-

I think that it is worth trying to understand some of the reasons we are heading towards a food crisis . The result of all of this deregulat...

© The Art of Engineering 2013 . Powered by Bootstrap , Blogger templates and RWD Testing Tool